Introduction to Leather Production Process

- Beamhouse Process

- Tanning Process

- Finishing Process

- Consumptions of Water and Chemicals of a Tannery

Introduction to Leather Production Process

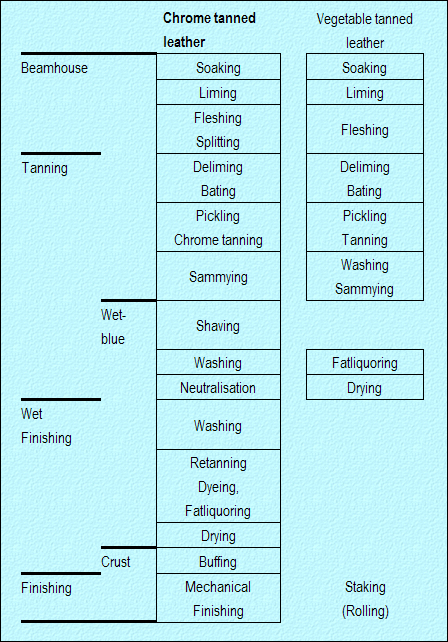

The leather production process is divided into three main stages namely beamhouse, tanning and finishing operations.In the beamhouse, there are soaking, liming, unhairing with sulfide, fleshing, trimming, deliming and bating processes to remove unwanted parts such as hair, skin, hoof, etc. The hides are then prepared for the subsequent tanning process. Tanning is to change decomposable raw hide to finished leather which is more stable, not decomposable, and resistant to weather condition and heat. After tanning, the hide or skin is kept in a comparatively stable stage for further trimming, selecting mechanical operation according to its quality. Then it is ready for sale or further processing. Finishing processes include re-tanning and fat-liquoring to improve quality of the tanned product, dyeing to achieve the customer's required colour, and spraying, pattern printing, etc to fulfill the market demand or customer requirement. Table 1-1 is the processing steps for leather production from raw hides.

Table 1-1 Process steps for the production of leather from raw hides

Beamhouse Process

Soaking

Soaking is carried out to allow hides and skins to re-absorb any water which may have been lost after flaying, to clean the hides and skins (removal of dung, blood, dirt etc), and to remove interfibrillary material. The soaking methods depend on the state of the hides. The process is mostly carried out in two steps: a dirt soak to remove the salt and dirt and a main soak.

Unhairing & liming of bovine hides

The function of liming and unhairing is to remove hair, interfibrillary components and epidermis and to open up the fibre structure…

Tanning Process

During tanning the collagen fibre is stabilised by cross-linking action of the tanning agents such that the hide is no longer susceptible to putrefaction or rotting. Furthermore their dimension stability, resistance to mechanical action and heat increase.

- mineral tannages

- vegetable tannins

- alternative tanning agents, which can be subdivided into

- syntans

- aldehydes

- oil tannage

Chromium and vegetable tanning agents are the most commonly used tanning agents.

Finishing Process

The overall objective of finishing is to enhance the appearance of the leather and to provide the performance characteristics expected of the finished leather with respect to:

- colour

- fashionable effects

- gloss

- handle

- flex, adhesion, rub fastness, as well as other properties including extensibility, break, light- and perspiration fastness, water vapour permeability and water resistance as required for the end use……

Consumptions of Water and Chemicals of a Tannery

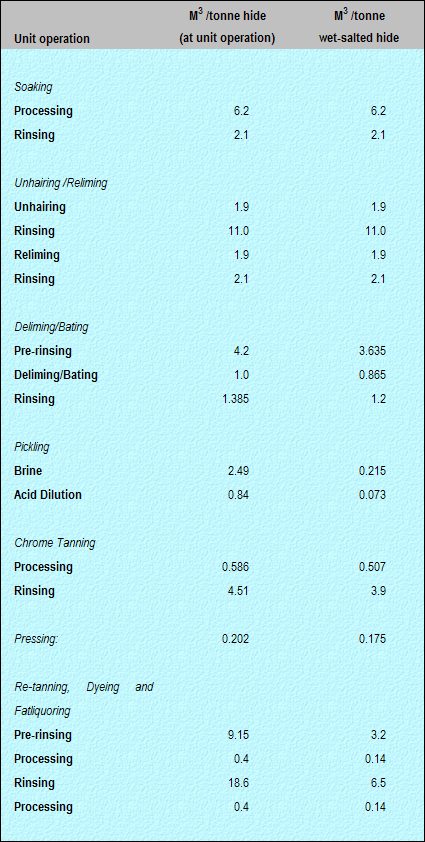

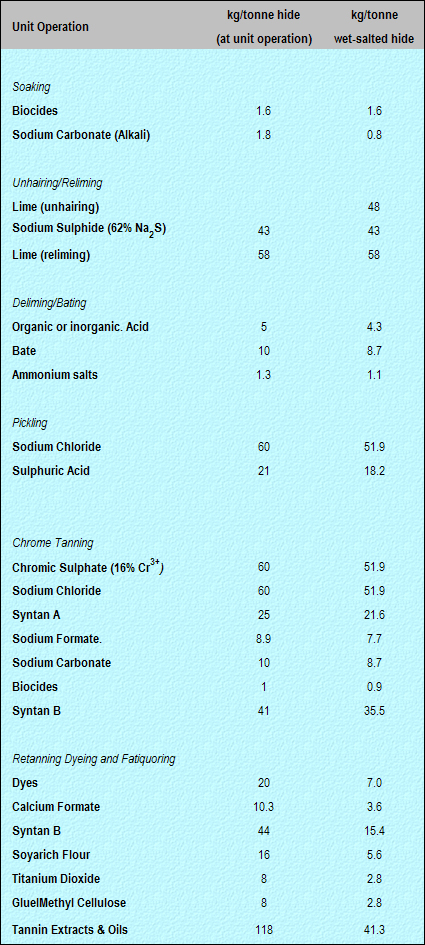

Leather tanning is a production process in which animal hides are transformed by using of water, chemicals and mechanical process. Following tables are data of the water and chemicals inputs per tannery unit operation of a tannery in South East Asia.

Water Inputs per Tannery Operation

Chemical Inputs per Tannery Unit Operation.

|