Sources of Waste

- Salted Stocks

- Soaking

- Unhairing and Liming

- Fleshing and Splitting

- Pelt Deliming and Bating

- Pickling and Chrome Tanning

- Sammying and Shaving

- Neutralisation, Re-tanning, Dyeing and Fat Liquoring for Chrome Tanned "Wet-Blue"

- Vegetable Tanning Process

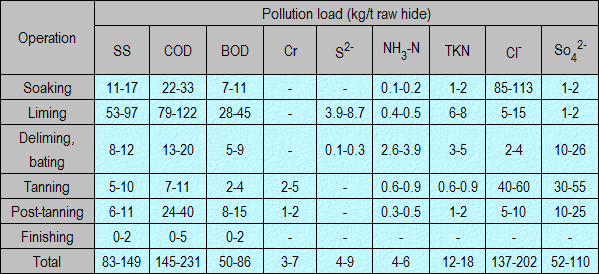

- Summary of Pollution Loads Discharged in Efluents from Individual Processing Operations

Leather production generates wastewater containing a high concentration of pollutants and solid waste. In this respect, the character of waste water, the pollution load as well as the amount of solid waste depend on the type of production process including the source of the tanning need to be identified. The main steps of leather processing which produce waste are as follows:

Salted Stocks

Preservation of raw hides is necessary to preserve raw hides from decomposition. Salt, about 20% on weight of material is normally used for pickling of raw hides. In addition, bactericides and insecticides are also used for preservation of hides. Therefore, prior to the actual tanning process, the salt must be removed which is normally carried out by shaking of the raw hides. This salt is the first type of solid waste generated by the leather tanning process……

Soaking

During this step hides are rehyrated. Surfactants and alkaline are added for the removal of dirt. The most important pollutants in soaking effluents are: salt, hide surface impurities, dirt and globular protein substances dissolved in water and salt solution……

Unhairing and Liming

Liming and unhairing is one of the steps which produce effluent with very high pollution load. Wastewater discharged from this step contains residues of hair, epidermis as well as other dirt accumulated in the hides……

Fleshing and Splitting

Hide which has been limed/unhaired will be fleshed by a scraping machine. Subsequently the defleshed hide will be split by “splitting machine”. Main waste generated from this step is fleshings and scraps from the lower part of hides……

Pelt Deliming and Bating

Pelt deliming and bating is used to reduce pH level of the pelt with the addition of ammonium salts and/or weak organic acids. Wastewater generated from this step will contain BOD, COD, salt, sulfate, ammonium, alkaline, suspended solid, and chloride. Ammonia gas is also emitted at this step.

Pickling and Chrome Tanning

Pickling is done to adjust pH level of the pelt to the range of 1.4 - 3.0 which is suitable for subsequent chrome tanning. Subsequently, basic chromium sulfate is added as tanning agent, reacting with protein in the hide. The wastewater from this step will contain acid, salt, suspended solid, BOD, COD, and chromium. Float residues will contain chromium, and will be discharged along with the effluent.

Sammying and Shaving

Sammying generates a certain amount of effluent which the composition is similar to the effluent from chrome tanning.

Neutralisation, Re-tanning, Dyeing and Fat Liquoring for Chrome Tanned "Wet-Blue"

Neutralisation is to increase the pH level to between 5 and 6 by adding sodium carbonate for the removal of residue chromium and to prepare wet-blue for subsequent re-tanning and dyeing processes. Therefore, chromium is present in the effluent from this step along with suspended solids.

Re-tanning is performed simultaneously with fat liquoring. Formic acid, syntans (synthetic tanning agent) and fat liquor are added. The chemicals which are not absorbed by the hides will be discharged along with the effluent in which chromium is also found.

Wet dyeing is usually applied to chrome tanned hides. It is to dye the entire hide. Chemicals, dyes, organic acid and hot water is applied for the completion of dyeing. All these substances are to be found in the effluent.

Vegetable Tanning Process

Vegetable tanning is carried out in rotating wooden drums by adding tanning agent extract from eucalyptus bark, quebraco tree, etc. The effluent from the subsequent two-stage washing step creates more problem. Washing of vegetable tanned hides is carried out with the addition of oxalic acid which will be discharged with the effluent along with the surplus vegetable tanning agent.

Summary of pollution loads discharged in effluents from individual processing operations

Summary of Pollution loads discharged in effluents from individual processing operations

|